CALL US TODAY! 918-221-9620

CALL US TODAY! 918-221-9620

PRODUCTS

PRODUCTS WE OFFER

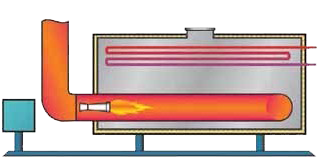

DPH INDIRECT BATH HEATER

The DPH Indirect Heater utilizes a proven concept since the 1930's. An intermediate bath media (e.g. water, eutectic salt, hot oil) is employed to immerse and separate the process coil from the firebox. The heat is transferred from the firebox to the bath media which in turn transfers it to the process coil. The process coil is totally isolated from any direct flame and/or combustion product contact associated with conventional direct fired heaters. Indirect Heaters range from 0.1 to 25 MMBtu/Hr.

SAFETY

The isolated firebox (combustion chamber) and process coil eliminates flame impingement. The low intermediate bath media temperature is controlled to prevent process thermodegradation and scaling

EMISSIONS

Options are available to provide your indirect heater with state-of-the-art low emission combustion systems to meet today's environmentally friendly requirements.

INSULATION

Light weight ceramic fiber insulation means less shipping and loading weight. Resistance to mechanical and thermal shock.

MULTI-FUEL CAPABILITY

Gaseous Fuel, Liquid Fuel (Distillate to #6 oil), Combination gas &oil, Low BTU Fuel supplemented with fuel blending.

TURNDOWN

The standard natural draft burner system has a3:1 turndown ratio. Optional automated forced draft burner systems are available to increase the turndown ratio.

EFFICIENCY

Basic indirect heaters are designed with 70-80% net thermal efficiency (NTE). Options to increase the NTE to 90% are available.

INSTALLATION

Low onsite installation cost. The indirect heater comes completely assembled with burner, fuel train and BPMS. Reassembly at site involves only nuts, bolts, and gaskets. NO onsite welding or special tools are required.

INSTRUMENTATION

The basic indirect heater includes our standard PLC burner management system (BMS). Options are available to provide a customized state-of-the-art MBS to meet any specification (e.g. IRI, NFPA, BASEEFA, and ATEX) and your specific information requirements.