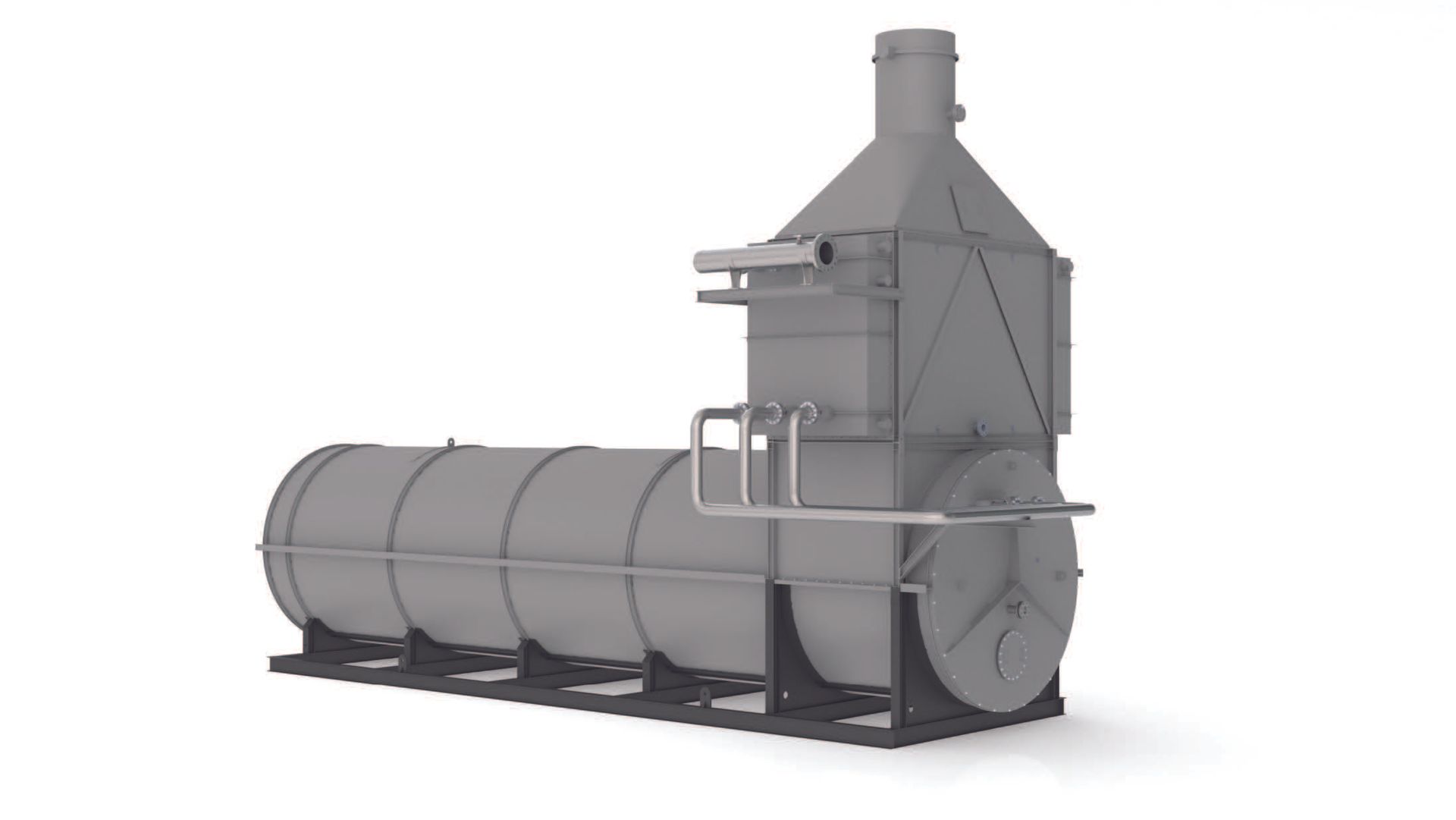

DPH PROCESS HEATER

ELITE-HE (API STYLE) HEATER

DPH ELITE-HE HEATER

Our line of high quality ELITE-HE heaters are designed to provide the midstream industry with high-efficiency and an easy-to-operate option,

bringing the best design for heating fluids and gas efficiently with emissions in mind. The DPH ELITE-HE heater design utilizes guidelines

from API 530 and API 560 as a basis, utilizing practices used for centuries in the petroleum industry to bring a midstream

option that is built robust, safe, with an eye for quality! With a "Patent Pending" design, we can meet your plant needs to bring about the best quality for your processing needs!

This is achieved with two separate isolated chambers that are custom designed, the radiant and convection section. These chambers are designed for optimum heat transfer and are standard 85% efficient. However, they can achieve efficiency upwards of 90% or more as required per the Client, or lower if requested. This heater can save fuel costs, bringing a payback that makes it a key partner in the plant's overall effectiveness.

All DPH ELITE-HE can utilize Ultra and Low NOx burners without any need for external flue gas recirculation

(FGR). DPH ELITE-HE heaters range from 1 to >100 MMBtu/Hr in a single heater.

SAFETY

The separate Radiant and Convection section eliminates process coil flame impingement. Combustion product's quenching eliminates process fluid thermo-degradation and scaling.

EMISSIONS

Options are available to provide your ELITE-HE heater with state-of-the-art low emission combustion systems to meet today's environmentally friendly requirements. Emissions of ULTRA Low-NOx of Sub 7 ppm or lower is achievable upon request. Low NOx 30ppm is per specification requirements, and <50ppm as a standard on offerings if no specification is given.

INSULATION

Lightweight ceramic fiber insulation means less shipping and loading weight, while offering resistance to mechanical and thermal shock. No warm-up period required. Less cold start-up and cool-down time. This allows the heater to immediately go to high-fire.

Safety

Elite's are built with Safety in mind and a design that will assure and mitigate risks on the job site. Utilizing a patent-pending design, our heaters can withstand what others in the industry prove to be unable to achieve.

TURNDOWN

The standard automated forced draft burner system has a 8:1 turndown ratio. Options to increase the turndown ratio are available.

EFFICIENCY

Basic ELITE-HE heaters are designed standard with 85% net thermal efficiency (NTE). Options to increase the NTE to 90% are available.

INSTALLATION

Low onsite installation cost. The ELITE-HE heater comes completely assembled with burner, fuel train and BMS. Reassembly at site involves only nuts, bolts, and gaskets. NO onsite welding or special tools are required.

INSTRUMENTATION

The ELITE-HE heater includes our standard burner management system (BMS). Options are available to provide a customized state-of-the-art BMS to meet any specification (e.g. IRI, NFPA, BASEEFA, and ATEX) and existing plant equipment to streamline operations, maintenance and spares.