HEATERS & AUXILLARY EQUIPMENT

DPH Capabilities

EFFICIENCY - DPH Heater Capabilities - DPH heaters are designed with 70-85% net thermal efficiency (NTE) without an economizer. Options to increase the NTE to 90% are available.

TURNDOWN - The standard automated forced draft burner system has a 8:1 turndown ratio, for the natural draft system it is a 3:1 turndown ratio. Options to increase the turndown ratio are available.

INSTRUMENTATION - The basic DPH heater includes our standard Burner Management System (BMS). Options are available to provide a customized state-of-the-art BMS to meet any specification (e.g. IRI, NFPA, BASEEFA, and ATEX) and your specific information requirements. Whatever you already have onsite, we can match easily to achieve commonality!

EMISSIONS - Options are available to provide the DPH heaters with state-of-the-art low emission combustion systems to meet today’s environmentally friendly requirements. Ultra-Low NOx of <5ppm - Low NOx of <30ppm, and Standard NOx of <60ppm are available.

Electric Heaters can achieve 0 NOx and CO2 Emissions

INSULATION - Light weight ceramic fiber insulation means less shipping and loading weight, while offering resistance to mechanical and thermal shock. No warm-up period required. Less cold start-up and cool-down time. Heater can immediately go to high-fire and begin processing.

MULTI - FUEL CAPABILITY - Depending on the type of heater. Gaseous Fuel, Liquid Fuel (Distillate to #6 oil), Combination gas & oil, Low BTU Fuel supplemented with fuel blending.

HEAT TRANSFER MEDIA SYSTEM - HMO heaters for heat media transfer applications can be furnished with a complete circulation system including: ASME Code expansion tank, circulation loop with bypass valves, and pump(s) with isolation valves.

INSTALLATION - Low onsite installation cost. DPH heaters come completely assembled with Burner, Fuel Train and Burner Management System. Reassembly at site involves only nuts, bolts, and gaskets. NO onsite welding or special tools are required.

OUR PRODUCTS

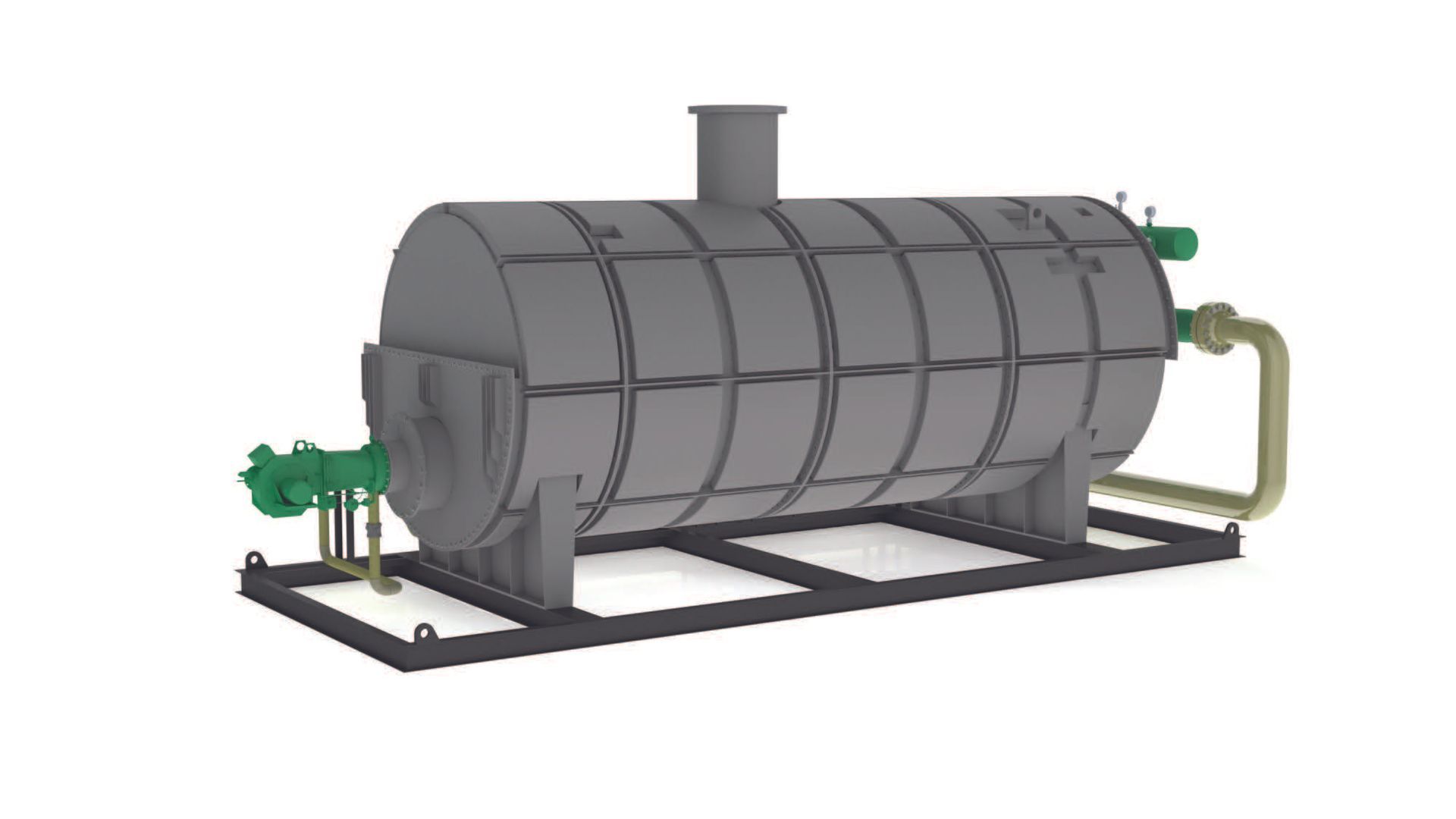

DPH “HELIFLO” HEATER – The DPH HELIFLO direct fired heater ranges in duty from 1MMBTu/Hr to 75 MMBtu/Hr. This heater is considered a two-pass flu gas heater, utilizing a tacked coil for radiant heat down the center, and convective heat transfer on the back side. All Heliflo heaters come standard with 80% efficiency, but can achieve higher as required by more surface area or utilizing a DPH Economizer.

DPH “ELITE-HE” HEATER – The DPH ELITE-HE heater is a radiant to convective heater designed with API guidelines for 2d spacing on the process coil, and a controlled separate heat transfer section bringing a unique solution to sensitive heating applications.

All ELITE-HE Heaters come standard with 85% efficiency, and can easily achieve more as required.

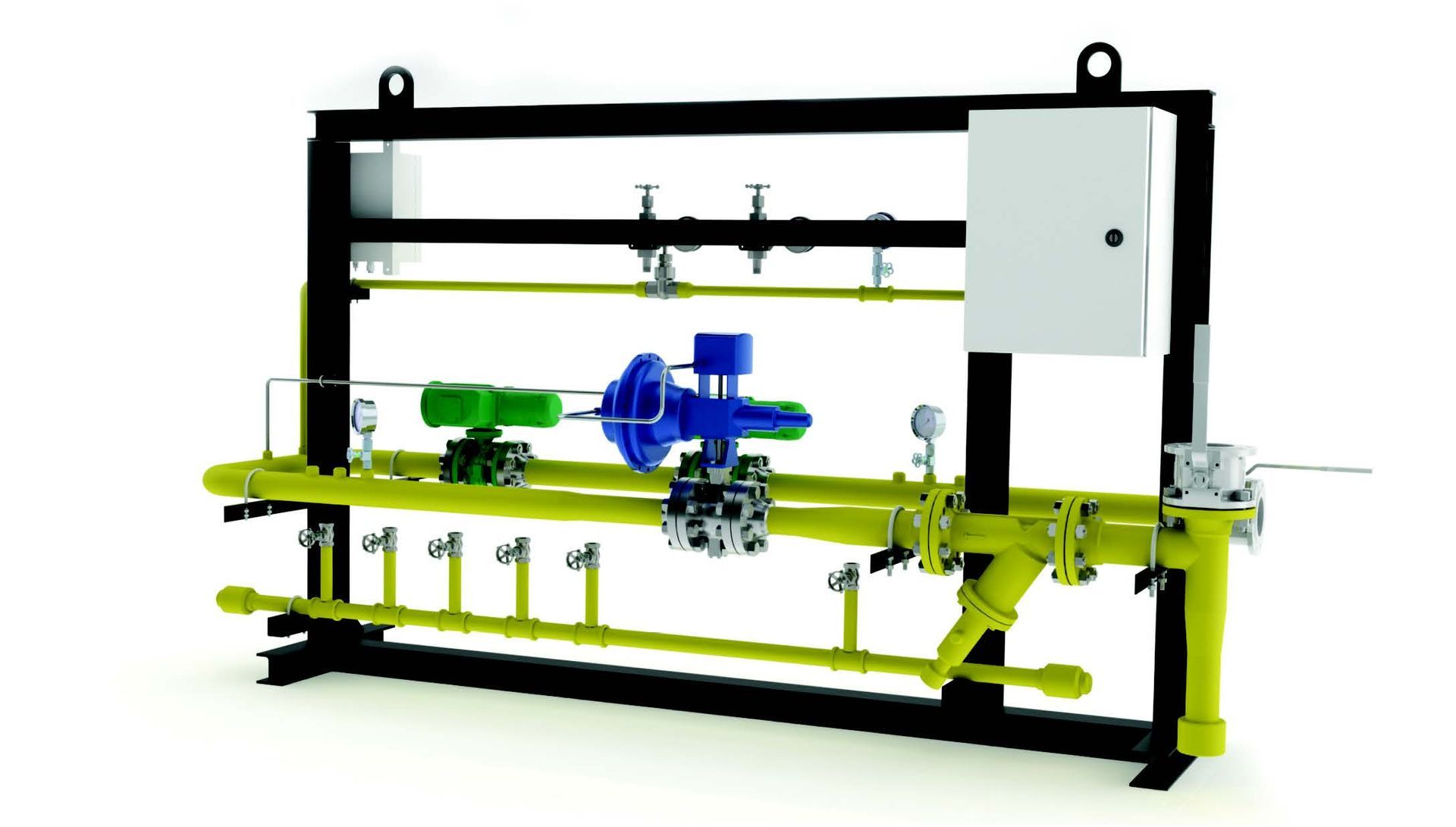

DPH “Combustion Management” Skid – Utilizing Code Piping of 1"-4" Nominal Pipe Size, DPH can provide a CMS package that is fully skidded to easily install, handle up to the maximum Heat Release required on your applications.

BMS will be rated per NFPA specific to the application requiring this skid.

DPH Circulation Skid – The DPH Circulation Skids are built ready to install and can be designed to fit any HMO or Fluid application. Our unique designs allow for modular sections to expand the skid as needed to meet the flow rates expected, to allow for filtration, and to connect the expansion tank if the client chooses not to install in the plant pipe rack. DPH Circulation Skids can come with 1-100% or 2 50% pumps, depending on Client requirements and needs.

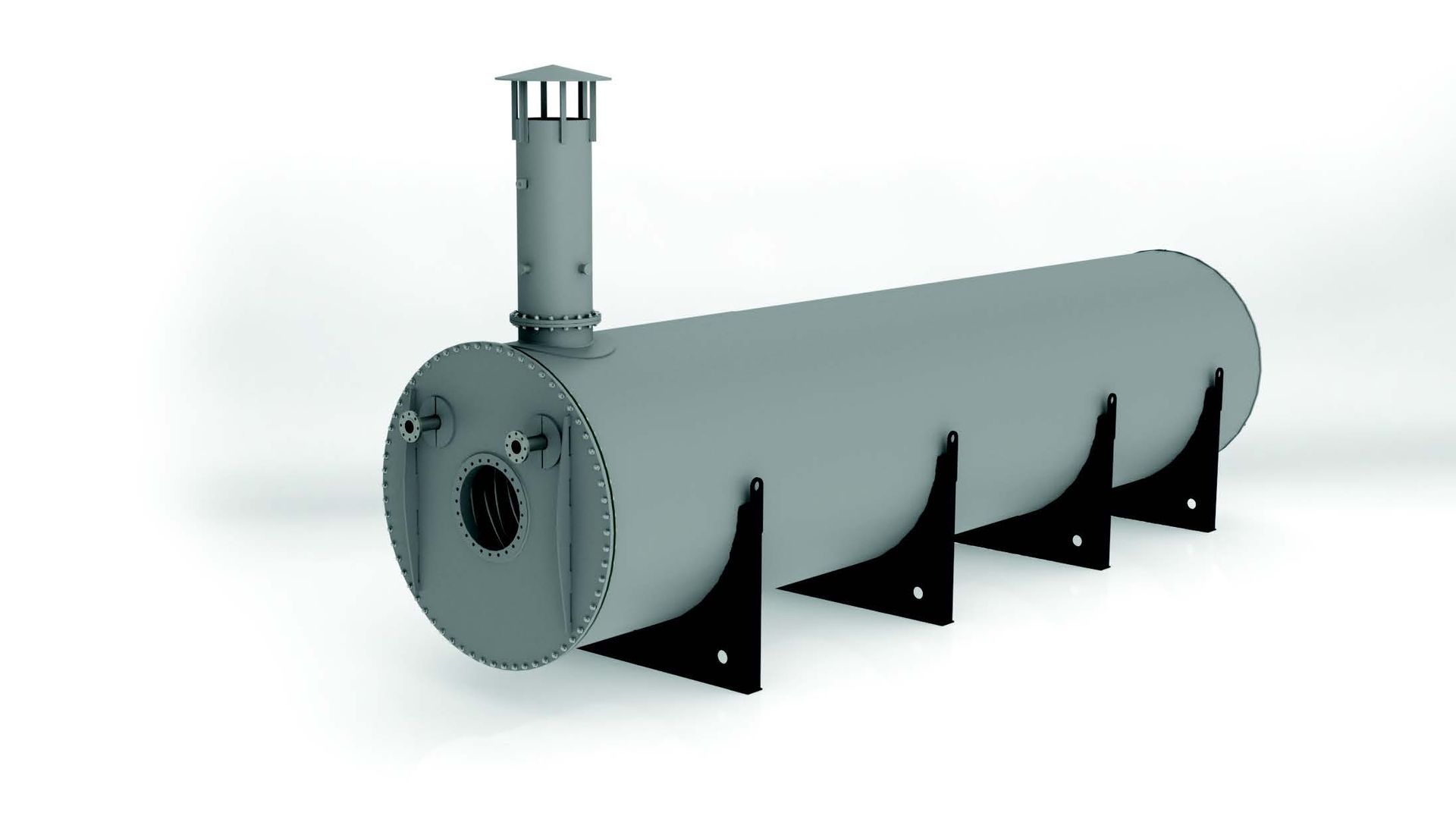

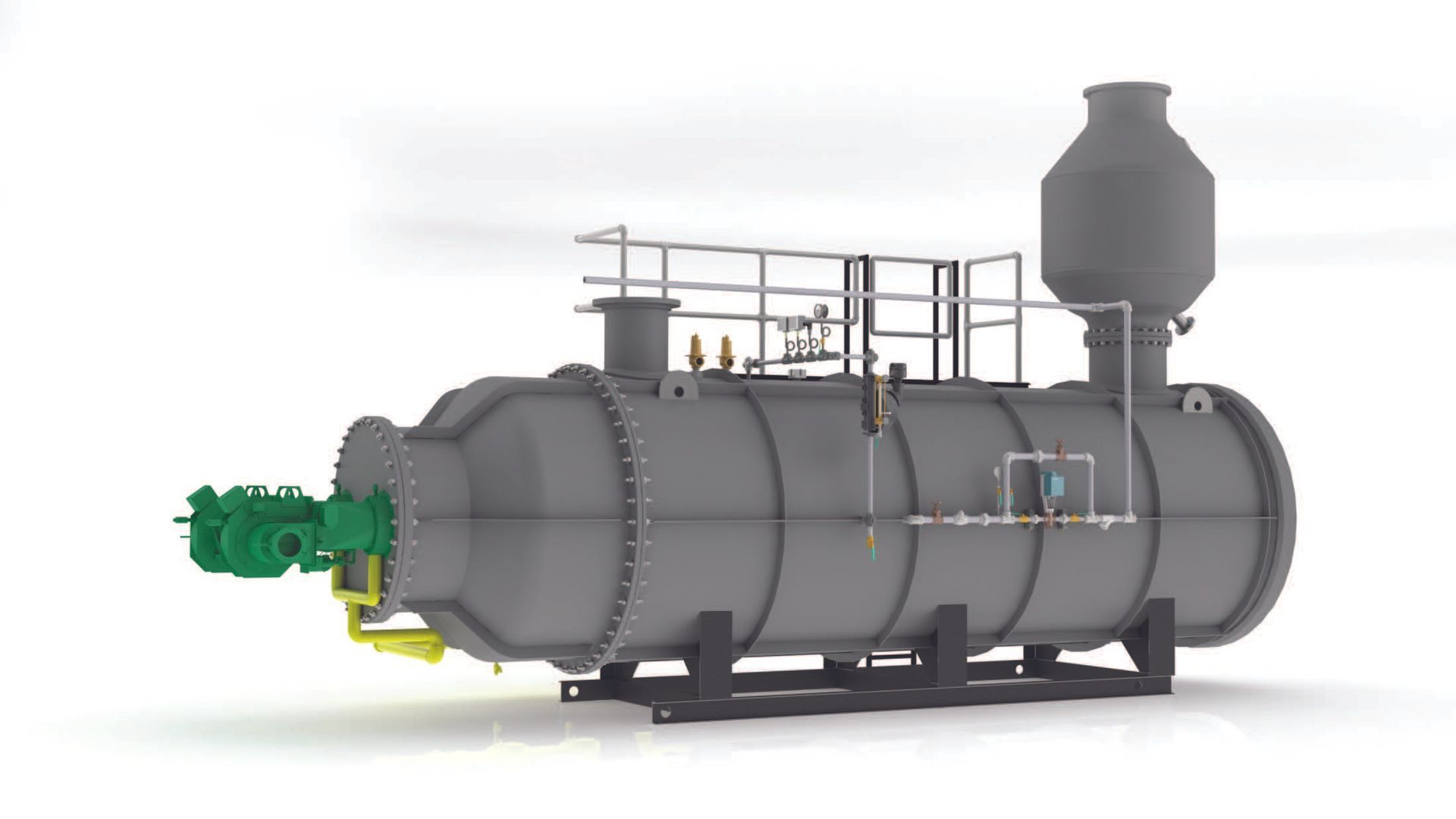

DPH INDIRECT HEATER – The DPH indirect heater utilizes a proven concept since the 1930’s, but with updated technology to assure the best design you can achieve on the market.

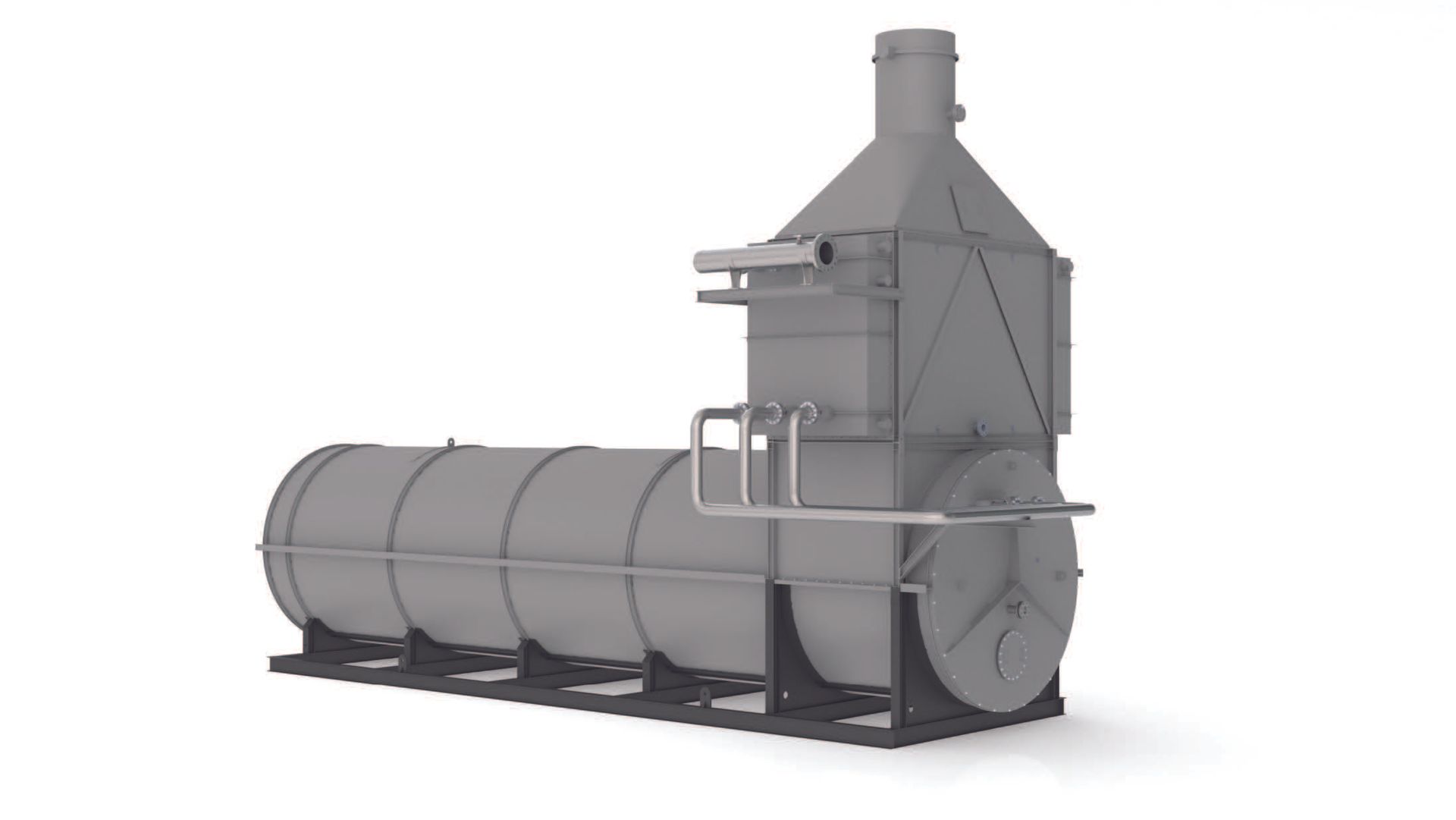

DPH THERMAL OXIDIZERS – The answer to your vapor emission problems (e.g. BTEX, VOC’s, THC‘s) is here. DPH’s Thermal Oxidizer single step approach with no required ancillary equipment (e.g. pumps, separators, or heat exchangers) is your solution.